PROFESSOR K.Y. CHAN

|

|

|

|

|

|

Hydrogen Generation from Formic Acid

Experiments are proposed to develop an efficient catalyst for selective decomposition of formic acid to generate hydrogen at low temperature. Materials optimization at the atomic, nanoscopic and large length scales will be sought by various synthetic attempts and advanced characterizations. Experiments will be performed to detect reaction intermediates, quantify isotope kinetic affects to help elucidate the reaction mechanism which has an undesirable alternative pathway of forming carbon monoxide and water. The project is built on preliminary results which show high activity and selectivity of a platinum-ruthenium based catalyst.

Room temperature generation of hydrogen from a relatively safe liquid fuel is

attractive for small fuel cells powering portable electronic devices. Formic

acid decomposition also plays a central role in low temperature aqueous phase

water-gas shift reaction for the generation of hydrogen from carbon monoxide

and water. The success of a low temperature water-gas shift reaction can help

clean coal gasification, generation of hydrogen as a clean fuel, and better

carbon capturing. These are the latest foci of clean energy research for better

environment.

(a) GC spectrum of a calibration gas mixture containing hydrogen, air, carbon monoxide, methane, & carbon dioxide. (b) GC spectrum of the product gas from formic acid decomposition showing only hydrogen, carbon dioxide, & air. The air was present initially above the formic acid reactor. The TCD detected H2/CO2peak area ratio is small than their concentration ratio due to their relative thermal conductivity.

|

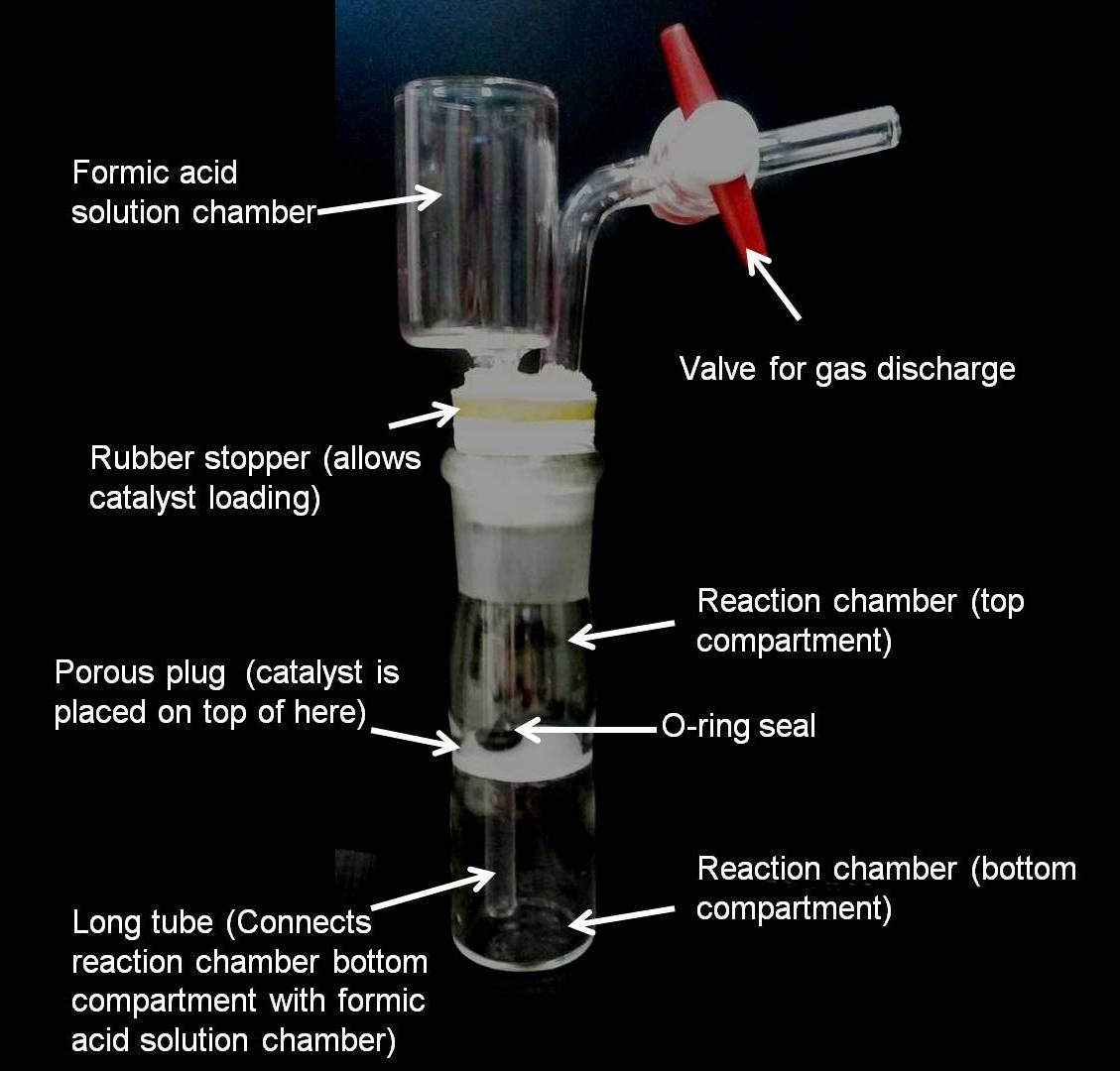

Set up to determine formic acid decomposition rates

& product compositions.

(Inert gas can be introduced to assist a steady flow when decomposition

rate is low. An additional gas chrommatogram can be used to determine

effectiveness of products separation by gravity.) |

HRTEM image of Pt-Ru nanoparticles supported in mesoporous carbon. The scale bar is 5 nanometers

| |

Video 1: Dehydrogenation of formic acid to give only hydrogen & carbon dioxide using the catalyst developed. (Please use Internet Explorier 8.0 or later and enable ActiveX controls to view video.) |

Video 2: The hydrogen generated through the use of this catalyst is able to power a small fan when fed to a hydrogen-air fuel cell made also by our group. (Please use Internet Explorier 8.0 or later and enable ActiveX controls to view video.)

|

|

|||

Prototype of stainless steel hydrogen generator with formic acid injection port, catalyst compartment and gas / FA solution storage chamber. Hydrogen is released through the valve on the side. (left) Partially disassembled view of the stainless steel hydrogen generator, with the sieved catalyst compartment and the septum (red) which forms part of the injection port clearly evident. (right)

|

Prototype of glass hydrogen generator with reaction chamber (porous plug in center for catalyst placement), formic acid solution chamber (with long tube extending down to reaction chamber) and gas outlet valve. Hydrogen accumulation within the top part of the reaction chamber results in formic acid solution being pushed up the FA solution chamber through the long tube and thus self-regulating the reaction.

|

[1] S. W. Ting, S. A. Cheng, K. Y. Tsang, N. van der Laak, and K. Y. Chan, "Low Activation Energy Dehydrogenation of Aqueous Formic Acid on Platinum-Ruthenium-Bismuth Oxide at Near-Ambient Temperature and Pressure", Chem. Comm.,web published 22 October 2009, DOI:10.1039/b916507j.

[2] K. Y. Chan, X. Zhang, C. M. Lam, A.C.C. Tseung, P. K. Shen, and J. K. You, “Methods and Apparatus for the Oxidation of Glucose Molecules”, US Patent 7,419,580 issued September 2008.